eScience Lectures Notes : Display Devices

Slide 1 : Display Technologies

Display Technologies

Video Displays

Slide 2 : Display Devices

Display Devices

Former lesson : importance of computer graphics in today world

As seen in the first lecture, there is a widespread recognition

of the power and utility of computer graphics in virtually all fields, a broad

range of graphics hardware and sofware are available. We will begin by having

a look at the displays device.

Slide 3 : Display Technologies

Cathode Ray Tubes (CRTs)

|

|

-

Most common display device today

-

Evacuated glass tube

-

Heating element (filament)

-

Electrons attracted to focusing anode cylinder

-

Vertical and Horizontal deflection plates

-

Beam strikes phosphor coating on front of tube

|

CRTs, or video monitors, are the most common output device

on computers today.

The figure below illustrates the basic structure of a CRT.

A CRT is an evacuated glass tube, with a heating element

on one end and a phosphor coated screen on the other.

When a current flows through this heating element, called a filament, the conductivity

of the metal filament is reduced due to the high temperature. This cause electrons

to pile up on the filament, because they can not move as fast as they would

like to. Some of these electrons actually boil off of the filament.

These free electrons are attracted to a strong positive charge from the outer

surface of the focusing anode cylinder (sometimes called an electrostatic lens).

However, the inside of the cylinder has a weaker negative charge. Thus when

the electrons head toward the anode they are forced into a beam and accelerated

by the repulsion of the inner cylinder walls in just the way that water is speeds

up when its flow though a smaller diameter pipe. By the time the electrons get

out they're going so fast that they fly past the cathode they were heading for.

The next thing that the electrons run into are two sets of weakly charged deflection

plates. These plates have opposite charges, one positive the other negative.

While their charge is not strong enough to capture the fast moving electrons

they do influence the path of the beam. The first set displaces the beam up

and down, and the second displaces the beam left and right. The electrons are

sent flying out of the neck of the bottle, until they smash into the phosphor

coating on the other end of the bottle.

The impact of this collision on the out valence bands of the phosphor compounds

knocks some of the electrons to jump into the another band. This causes a few

photons to be generated, and results in our seeing a spot on the CRT's face.

Slide 4 : Vector Displays

Vector Displays

|

|

-

Oscilloscopes were some of the 1st computer displays

-

Used by both analog and digital computers

-

Computation results used to drive the vertical and horizontal axis

(X-Y)

-

Intensity could also be controlled (Z-axis)

-

Used mostly for line drawings

-

Called vector, calligraphic or affectionately stroker

displays

-

Display list had to be constantly updated

(except for storage tubes)

|

Tektronix 4014

|

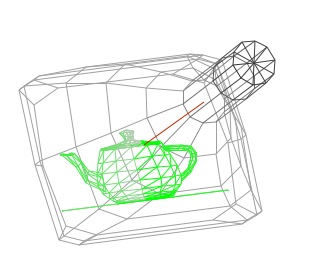

CRTs were embraced as output devices very early in the

development of digital computers.

There close cousins, vacuum tubes, were some of the first

switching elements used to build computers. Today, the CRT is a the last remaining

vacuum tube in most systems (Even the flashing lights are solid-state LEDs).

Most likely, oscilloscopes were some of the first computer graphics displays.

The results of computations could be used to directly drive the vertical and

horizontal displacement plates in order to draw lines on the CRT's face. By

varying the current to the heating filament the output of the electron beam

could also be controlled. This allowed the intensity of the lines to vary from

bright to completely dark.

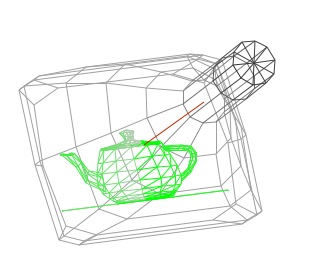

These early CRT displays were called vector, calligraphic or affectionately

stroker displays. The demonstration above gives some feel for how they worked.

By the way, this demo is an active Java applet. You can click and drag your

mouse inside of the image to reorient the CRT for a better view. Notice the

wireframe nature of the displayed image. This demo is complicated by the fact

that it's a wireframe simulation of a wireframe display system. Notice how the

color of the gray lines of the CRT vary from dark to light indicating which

parts of the model that are closer to the viewer. This technique is called depth-cueing,

and it was used frequently on vector displays.

The intensity variations seen on the teapot, however, are for a different reason.

Eventually, the phosphors recover from their excited state and the displaced

electrons return back to their original bands. The glow of the phosphor fades.

Thus, the image on the CRT's face must be constantly redrawn, refreshed, or

updated. The two primary problems with vector displays are that they required

constant updates to avoid fading, thus limiting the drawn scene's complexity,

and they only drew wireframes.

Slide 5 : Raster Displays

Raster Displays

|

-

TV boomed in the 50s and early 60s

(they got cheap)

-

B/W TVs are basically oscilloscopes

(with a hardwired scan pattern)

-

Entire screen painted 30 times/sec

-

Screen is traversed 60 times/sec

-

Even/Odd lines on alternate scans

(called fields)

-

Interlace - a hack to give

-

Smooth motion

on dynamic scenes

-

High Resolution

on static scenes

-

Optimize bandwidth

|

During the late 50s and early 60s, broadcast television,

really began to take off. It had been around for a while, but it didn't become

a commodity item until about this time. Televisions are basically just oscilloscopes.

The main difference is that instead of having complete control over the vertical

and horizontal deflection, a television sweeps its trace across the entire face

in a regular fixed pattern (the actual details are slightly more complicated,

but that's the jist of it). This scanning pattern proceeds from the top-left

of the screen to the bottom-right as shown in the diagram.

The final result is that the entire screen is painted once every 1/30th of a

second (33 mS) in USA and once every 1/25th in europe or in Australia.

Televisions were mass produced and inexpensive. For a

computer to paint the entire screen it needs only to synchronize its painting

with the constant scanning pattern of the raster. The solution to this problem

was to add a special memory that operated synchronous to the raster scanning

of the TV, called a frame buffer.

While televisions were cheap, memory wasn't. So there was a long period where

the patterns were scanned out of a cheap high-density read-only memories, called

character generators. The trick was to use a single 8 bit code to specify an

8 by 12 character pattern from the ROM, and with a few addressing tricks one

could build a nice display (80 by 25 character) with only 2 kilobytes of memory.

Thus the era of the CRT-terminal was born.

Slide 6 : Character Based Frame Buffer

Raster Display

|

In a raster display the path of the electron beam

is hardwired. The computer must synchronize its "painting" of

the screen with the scanning of the display. The computer only controls

the intensity of the color at each point on the screen. Usually a dedicated

section of memory, called the frame buffer, is used to store these intensity

variations.

|

The simulation above is a Java applet that simulates the

scanning of a raster display. Move the CRT wireframe (by clicking and dragging)

in order to get a better feel.

There were a few attempts at building systems with downloadable or programmable

character generators. And a few systems added an extra byte to specify the foreground

and background colors of the character cell. Lots of tank/maze arcade games

in the 70's worked this way. But by the late 70's and early 80's the price of

memory started a free-fall and the graphics terminal was born. In a later lecture

we'll go into a lot more detail about the notion of a framebuffer an how it

is fundamental to modern computer graphics.

Slide 7 :

Color Video

Color Video

Delta Electron Gun Arrangement

|

Color CRTs are much more complicated

-

Requires precision geometry

-

Patterned phosphors on CRT face

-

Aligned metal shadow mask

-

Three electron guns

-

Less bright than monochrome CRTs

|

In-line Electron Gun Arrangement

|

Color CRT's are more complicated than the simple monochrome

models summarized before. The phosphors on the face of a color CRT are laid

out in a precise geometric pattern. There are two primary variations, the stripe

pattern of in-line tubes shown on the left, and the delta pattern of delta tubes

as shown on the right.

Within the neck of the CRT there are three electron guns, one each for red,

green, and blue (the actual beams are all the same color-- invisible). There

is also a special metal plate just behind the phosphor cover front face, called

a shadow mask. This mask is aligned so that it simultaneously allows each electron

beam to see only the phosphors of its assigned color and blocks the phosphor

of the remaining two colors.

The figure shown above shows the configuration of an example in-line tube. On

page 44 of Hearn & Baker you'll see a similar diagram for a delta electron

gun configuration

A significant portion of the electron beam's energy strikes the mask rather

than the phosphors. This has two side effects. The shadow mask has to be extremely

rigid to stay aligned with the phosphor patterns on the CRT face. The collision

of electrons with metal mask causes the mask to emit some of it absorbed energy

as electromagnetic radiation. Most of this energy is in the form of heat, but

some fraction is emitted as x-rays. X-rays can present a health hazard. This

wasn't a large problem for television because the intensity of the x-ray radiation

falls off quickly as you move away from the screen. However, computer monitors

are supposed to be viewed from a short distance. This health concern along with

the high voltages and power dissipations of CRTs has motivated the development

of new display technologies.

For more information on CRTs check out the following links:

The History

of the Cathode Ray Tube

The Scoop on CRTs

History

Slide 8 : Cathode Ray Tubes Summary

Raster Display Summary

|

Disadvantages

-

Requires screen-sized memory array

-

Discrete spatial sampling (pixels)

-

Moire patterns result when shadow-mask and dot-pitch frequencies

are mismatched

-

Convergence (varying angles of approach distance of e-beam across

CRT face)

-

Limit on practical size (< 40 inches)

-

Spurious X-ray radiation

-

Occupies a large volume

Advantages

-

Allows solids to be displayed

-

Leverages low-cost CRT H/W (TVs)

-

Whole Screen is constantly updated

-

Bright light-emitting display technology

|

Slide 9 : Comparison CRT / LCD

Comparison CRT / LCD

Cathode Ray Tubes

|

Liquid Crystal Displays (LCDs)

|

Advantages

-

Fast repsonse (high resolution possible)

-

Full color (large modulation depth of E-beam)

-

Saturated and natural colors

-

Inexpensive, matured technology

-

Wide angle, high contrast and brightness

|

Advantages

-

-

Light weight (typ. 1/5 of CRT)

-

Low power consumption (typ. 1/4 of CRT)

-

Completely flat screen - no geometrical errors

-

Crisp pictures - digital and uniform colors

-

No electromagnetic emission

-

Fully digital signal processing possible

-

Large screens (>20 inch) on desktops

|

Disadvantages

-

Large and heavy (typ. 70x70 cm, 15 kg)

-

High power consumption (typ. 140W)

-

Harmful DC and AC electric and magnetic fields

-

Flickering at 50-80 Hz (no memory effect)

-

Geometrical errors at edges

|

Disadvantages

-

High price (presently 3x CRT)

-

Poor viewing angle (typ. +/- 50 degrees)

-

Low contrast and luminance (typ. 1:100)

-

Low luminance (typ. 200 cd/m2)

|

|

|

Slide 10 : Liquid Crystal Displays (LCDs)

Liquid Crystal Displays (LCDs)

Currently, the most popular alternative to the CRT is the Liquid Crystal Display

(LCD). LCDs are organic molecules that, in the absence of external forces, tend

to align themselves in crystalline structures. But, when an external force is

applied they will rearrange themselves as if they were a liquid. Some liquid

crystals respond to heat (i.e. mood rings), others respond to electromagnetic

forces.

When used as optical (light) modulators LCDs change polarization rather than

transparency (at least this is true for the most popular type of LCD called

Super-twisted Nematic Liquid crystals). In their unexcited or crystalline state

the LCDs rotate the polarization of light by 90 degrees. In the presence of

an electric field, LCDs the small electrostatic charges of the molecules align

with the impinging E field.

The LCD's transition between crystalline and liquid states is a slow process.

This has both good and bad side effects. LCDs, like phosphors, remain "on"

for some time after the E field is applied. Thus the image is persistent like

a CRT's, but this lasts just until the crystals can realign themselves, thus

they must be constantly refreshed, again, like a CRT.

The book Hearns & Baker is a little confusing in describing

how LCDs work (pp. 47-48). They call the relaxed state the "On State"

and the excited state the "Off State". Their statement is only true

from the point of view of the pixels when the LCDs are used in a transmissive

mode (like on most laptops). The opposite is true when the LCDs are used in

a reflective mode (like on watches).

Slide 11 : Reflective and Backlit LCDs

Reflective and Backlit LCDs

Rather than generating light like a CRTs, LCDs act as

light values. Therefore, they are dependent on some external light source. In

the case of a transmissive display, usually some sort of back light is used.

Reflective displays take advantage of the ambient light. Thus, transmissive

displays are difficult to see when they are overwhelmed by external light sources,

whereas reflective displays can't be seen in the dark.

You should also note that at least half of the light is

lost in most LCD configurations. Can you see why?

Slide 12 : Active Matrix LCDs

Active Matrix LCDs

Active Matrix LCDs (aka Thin Film Transistor (TFT))

The LCD's themselves have extremely low power requirements.

A very small electric field is required to excite the crystals into their liquid

state. Most of the energy used by an LCD display system is due to the back lighting.

It was mentioned earlier that LCD's slowly transition back to their crystalline

state when the E field is removed. In scanned displays, with a large number

of pixels, the percentage of the time that LCDs are excited is very small. Thus

the crystals spend most of their time in intermediate states, being neither

"On" or "Off". This behavior is indicative of passive displays.

You might notice that these displays are not very sharp and are prone to ghosting.

Another way to building LCD displays uses an active matrix. The individual cells

are very similar to those described above. The main difference is that the electric

field is retained by a capacitor so that the crystal remains in a constant state.

Transistor switches are used to transfer charge into the capacitors during the

scanning process. The capacitors can hold the charge for significantly longer

than the refresh period yielding a crisp display with no shadows. Active displays,

require a working capacitor and transistor for each LCD or pixel element, and

thus, they are more expensive to produce.

TFT displays

Many companies have adopted Thin Film Transistor (TFT)

technology to improve colour screens. In a TFT screen, also known as active

matrix, an extra matrix of transistors is connected to the LCD panel - one transistor

for each colour (RGB) of each pixel. These transistors drive the pixels, eliminating

at a stroke the problems of ghosting and slow response speed that afflict non-TFT

LCDs. The result is screen response times of the order of 25ms, contrast ratios

in the region of 200:1 to 400:1 and brightness values between 200 and 250 cd/m2

(candela per square metre).

The liquid crystal elements of each pixel are arranged so that in their normal

state (with no voltage applied) the light coming through the passive filter

is 'incorrectly' polarised and thus blocked. But when a voltage is applied across

the liquid crystal elements they twist by up to ninety degrees in proportion

to the voltage, changing their polarisation and letting more light through.

The transistors control the degree of twist and hence the intensity of the red,

green and blue elements of each pixel forming the image on the display.

TFT screens can be made much thinner than LCDs, making them lighter, and refresh

rates now approach those of CRTs as the current runs about ten times faster

than on a DSTN screen. VGA screens need 921,000 transistors (640 x 480 x 3),

while a resolution of 1024 x 768 needs 2,359,296 and each has to be perfect.

The complete matrix of transistors has to be produced on a single, expensive

silicon wafer and the presence of more than a couple of impurities means that

the whole wafer must be discarded. This leads to a high wastage rate and is

the main reason for the high price of TFT displays. It’s also the reason

why in any TFT display there are liable to be a couple of defective’ pixels

where the transistors have failed.

There are two phenomenon which define a defective LCD pixel:

A 'lit' pixel, which appears as one or several randomly-placed red, blue and/or

green pixel elements on an all-black background, or

a 'missing' or 'dead' pixel, which appears as a black dot on all-white backgrounds.

The former is the more common and is the result of a transistor occasionally

shorting on, resulting in a permanently 'turned-on' (red, green or blue) pixel.

Unfortunately, fixing the transistor itself is not possible after assembly.

It is possible to disable an offending transistor using a laser. However, this

just creates black dots which would appear on a white background. Permanently

turned on pixels are a fairly common occurrence in LCD manufacturing and LCD

manufacturers set limits - based on user feedback and manufacturing cost data

- as to how many defective pixels are acceptable for a given LCD panel. The

goal in setting these limits is to maintain reasonable product pricing while

minimising the degree of user distraction from defective pixels. For example,

a 1024x768 native resolution panel - containing a total of 2,359,296 (1024x768x3)

pixels - which has 20 defective pixels, would have a pixel defect rate of (20/2,359,296)*100

= 0.0008%.

TFT panels have undergone significant evolution since the days of the early,

Twisted Nematic (TN) technology based panels.

Slide 13 : Plasma Display Panels

Plasma Display Panels

|

|

-

Promising for large format displays

-

Basically fluorescent tubes

-

High-voltage discharge excites gas mixture (He, Xe)

-

Upon relaxation UV light is emitted

-

UV light excites phosphors

-

Large viewing angle

|

-

Less efficient than CRTs

-

Not as bright

-

More power

-

Large pixels (~1mm compared to 0.2mm for CRT)

-

Ion bombardment depletes phosphors

|

|

Plasma display panels (PDPs) are essentially a matrix of very small fluorescent

tubes with red, green, and blue phosphors. As in ordinary tubes, a discharge

is initiated by a high voltage which excites a mixture of inert-gases such as

He and Xe. Upon relaxation, ultra-violet (UV) radiation is generated which excites

the phosphors.

PDPs provide a large viewing angle since the phosphors emit light uniformly.

A 40-inch PDP typically consumes about 300 W whereas the peak brightness is

only 1/3 of that of a CRT consuming about half the power. Sealing and vacuum

pressure support problems apply to PDPs as well, requiring thicker glass as

the screen is enlarged. In addition, the discharge chambers have pixel pitches

of more than 1 mm which makes it difficult to construct high-definition television

(HDTV) and work-station monitors. By contrast, TFTLCDs, CRTs and FEDs may have

pixel pitches as small as 0.2 mm.

Slide 14 : Field Emission Devices (FEDs)

Field Emission Devices (FEDs)

PixTech |

|

-

Works like a CRT with multiple electron guns at each pixel

-

Uses modest voltages applied to sharp points to produce strong E

fields

-

Reliable electrodes proven difficult to produce

-

Limited in size

-

Thin, and requires a vacuum

|

Field Emission Display: a display technology which use

vacuum tubes (one for each pixel) with conventional RGB phosphors.

Slide 15 : Digital Micromirror Devices (DMDs)

Digital Micromirror Devices (DMDs)

(aka Digital Light Processing / DLP / commercial name)

(A Micro-Optical Electromechanical Device - MOEMS - for Display Applications)

|

Texas Instruments

|

-

Microelectromechanical (MEMs) devices

-

Fabricated using VLSI processing techniques

-

2-D array of mirrors

-

Tilts +/- 10 degrees

-

Electrostatically controlled

-

Truly digital pixel

|

|

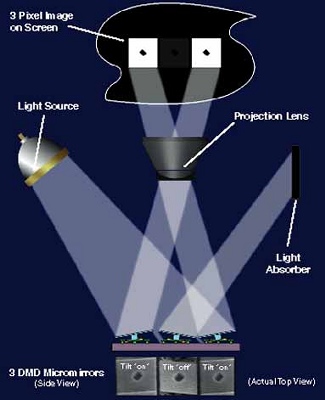

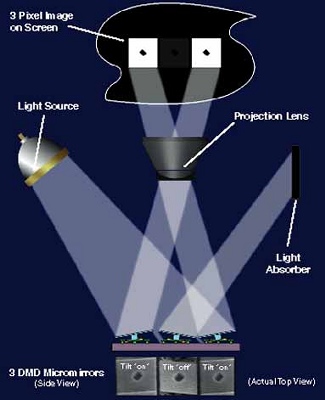

Three Mirrors Project Image

Incoming light hits the three mirror pixels. The

two outer mirrors that are turned on reflect the light through the projection

lens and onto the screen. These two "on" mirrors produce square,

white pixel images. The central mirror is tilted to the "off"

position. This mirror reflects light away from the projection lens to

a light absorber so no light reaches the screen at that particular pixel,

producing a square, dark pixel image. In the same way, the remaining mirror

pixels reflect light to the screen or away from it. By using a color filter

system and by varying the amount of time each of the DMD™ mirror

pixels is on, a full-color, digital picture is projected onto the screen.

|

-

Suitable only for projection displays

-

Gray levels via Pulse-Width Modulation (PWM)

-

Color via multiple chips or a color-wheel

-

Excellent resolution and fill-factor

-

Light efficient

-

Problems with stray light and flicker

|

SXGA DMD on Hand

SXGA device with black aperture: 1280x1024; 1,310,720 mirrors |

DMD™ and Ant Leg

Micrographic photo of ant leg on the DMD surface. Each mirror is 16 µm2

with 1µm separation between pixels

|

Digital Micromirror Device: an array of semiconductor-based

digital mirrors that precisely reflect a light source for projection display

and hard-copy applications. A DMD enables Digital Light Processing and displays

images digitally. Rather than displaying digital broadcast signals as analogue

signals, a DMD directs the digital signal directly to your screen.

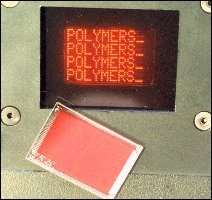

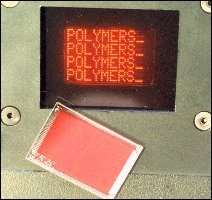

Slide 16 : Light Emitting Diode (LED) Arrays

Light Emitting Diode (LED) Arrays

|

-

Organic Light Emitting Diodes (OLEDSs)

-

Function is similar to a semiconductor LED

-

Thin-film polymer construction

-

Potentially simpler processing

-

Transparent

-

Flexible

|

|

-

Can be vertically stacked

-

Excellent brightness

-

Large viewing angle

-

Efficient (low power/low voltage)

-

Fast (< 1 microsec)

-

Can be made large or small

-

Tend to breakdown

|

A display device consisting of a series of carbon-based thin films sandwiched

between two electrodes; one transparent (often glass). OLED technology holds

promise because of the ability to tailor the organic molecules to vary color

saturation, sensitivity, and other optical properties.

The operation of organic LEDs is similar to inorganic

semiconductor LEDs. When two materials, one with an excess of mobile electrons

the other with a deficiency, are place in close contact, a junction region is

formed. When a small potential is applied, the resistance of this junction to

the transport of electrons can be overcome. The motion of the electrons in an

LED excites the electron on lower valance bands, causing them to move up or

down into other bands. This configuration is unstable and the electrons quickly

return to their previous state. This change in energy (induced by the electrons

returning to their proper valence bands) causes a photon to be emitted.

Unlike crystalline semiconductors, though, these organic

devices are made by depositing a thin-film layer from a solution or by a vacuum

deposition process. They are not grown like a crystal, and they do no require

a high-temperature process to dope them. This allows large areas to be processed,

unlike typical semiconductor fabrication.

Several recent developments have stimulated significant

interest in OLEDs. These include new materials and new processes. The performance

of prototype systems has been very promising. It appears likely that commercial

display products will appear in the near future.

OLEDs have many advantages. They are light-emitting, low-voltage,

full-color, and have an easily produced electronic structure. All other light-emitting,

flat panel technologies employ high voltages. The simple structure is clearly

not a characteristic of other popular flat panel display types.

OLED development has progressed rapidly, but there is still much work to be

done. Display lifetime remains a key issue with OLEDs. Many of the researchers

already feel confident that these problems can be overcome.

Slide 17 : Other Flat Panel Display Technologies (FPD)

Other Flat Panel Display Technologies (FPD)

-

Thin film electroluminescent displays ( TFEL )

-

Electrochromic displays ( ECD )

-

Thermochromic displays ( TCD )

-

Plasma addressed liquid crystal displays ( PALC )

-

Microdisplays on CMOS backplanes

The one we have seen :

Light emitting diode arrays ( LED )

Organic luminescent displays ( OELD )

Micro-Optical Electromechanical Systems ( MOEMS )

Slide 18 : Overhead projectors

Overhead projectors : Some examples of commercial products

| CRT |

LCD |

Barco

|

Nec : Short Persistence Phosphor CRT

MultiSync XG85S |

Barco |

NEC MultiSync GT series LCD projector |

| DMD / DLP |

|

|

Barco

|

Nec |

|

Barco

Barco : http://www.barco.com/projection_systems/

NEC

Nec Projectors : http://www.nec-pj.com/ind_pj.htm

or : http://www.nectech.com/presentationproducts/product_info/disc_series.cfm?divisionid=3

Nec for the Wedge :

2 NEC Multisync XG75 : CRT Projector

Video Projector to include the following: 3 picture tubes, 3 lenses,

direct projection system; can be ceiling mounted; capable of 1280 x 1024

pixels or 1500 TV lines; at least 1100 lumens at 10% peak white; horizontal

scanning frequency of 15 to 75 kHz; ability to project on fat, curved,

or tilted screens; allows input from video and computer sources; remote control

with control with control input selection, power on/off, RGB selection, brightness

control, sharpness control, hue, picture control, and volume control; includes

hardware and operators manual; two year limited warranty on parts and labor;

all necessary cables and parts for connection; setup (includes mounting to bracket,

connecting to computer, VCR, visual presenter, laserdisc player, and control

system, and setting convergence with computer and video sources.)

Slide 19 : Immersion

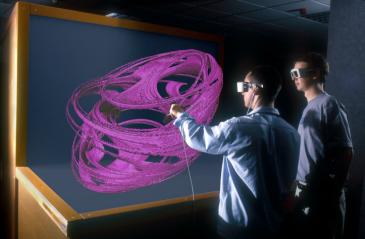

Immersion

From 3D on a screen to Virtual Reality

Most often we present 3-dimensional graphics on 2-dimensional displays.

What is the potential for presenting 3D information in a way that it can be

percieved as 3D?

Virtual Reality = Computer Graphics in Real Time + Immersion

+ Interaction + other perceptive feedback (touch, sound, smell...)

Terminology by K.-P. Beier

The term 'Virtual Reality' (VR) was initially coined by Jaron Lanier, founder

of VPL Research (1989). Other related terms include 'Artificial Reality' (Myron

Krueger, 1970s), 'Cyberspace' (William Gibson, 1984), and, more recently, 'Virtual

Worlds' and 'Virtual Environments' (1990s).

Today, 'Virtual Reality' is used in a variety of ways and often in a confusing

and misleading manner. Originally, the term referred to 'Immersive Virtual Reality.'

In immersive VR, the user becomes fully immersed in an artificial, three-dimensional

world that is completely generated by a computer.

Characteristics of Immersive VR

The unique characteristics of immersive virtual reality can be summarized as

follows:

- Head-referenced viewing provides a natural interface

for the navigation in three-dimensional space and allows for look-around,

walk-around, and fly-through capabilities in virtual environments.

- Stereoscopic viewing enhances the perception of depth

and the sense of space.

- The virtual world is presented in full scale and relates

properly to the human size.

- Realistic interactions with virtual objects via data

glove and similar devices allow for manipulation, operation, and control of

virtual worlds.

- The convincing illusion of being fully immersed in

an artificial world can be enhanced by auditory, haptic, and other non-visual

technologies.

- Networked applications allow for shared virtual environments

(see below).

Slide 20 : Immersion Technology

Immersion Technologies

From simple little flat screen to CAVEs

TAN Projection Technology :

http://www.tan.de/english/intro.html

Slide 21 : Computer Screen

Computer Screen...

spherical one ? ....... Elumens :

Slide 22 : Head-Mounted Display (HMD)

Head-Mounted Display (HMD)

|

|

|

UP :

Modern inexpensive HMD: The General Reality CE-200W. (Photo: General

Reality Corp.)

|

-

Two miniature dsiplays

-

Two image pipelines

-

A motion tracker

The head-mounted display (HMD) was the first device providing

its wearer with an immersive experience. Evans and Sutherland demonstrated a

head-mounted stereo display already in 1965. The EyePhone from VPL Research

was the first commercially available HMD (1989).

A typical HMD houses two miniature display screens

and an optical system that channels the images from the screens to the eyes,

thereby, presenting a stereo view of a virtual world. A motion tracker

continuously measures the position and orientation of the user's head

and allows the image generating computer to adjust the scene representation

to the current view.

As a result, the viewer can look around and walk through

the surrounding virtual environment.

Issues : Heavy

Consider carrying two displays around on your head.

+ Stereopsis is a strong

3D queue

+ Existing Technology

+ Personal Display

- Obtrusive

- Narrow FOV

(Tunnel Vision)

- Low Resolution

- Tracking

Currently the most popular 3-Dimensional (VR) display

What is the best way to get steroscopique view of two

scenes : it is by giving one differente image to each eyes

To overcome the often uncomfortable intrusiveness of a

head-mounted display, alternative concepts (e.g., BOOM

and CAVE) for immersive viewing of virtual environments

were developed.

Slide 23 : BOOM

BOOM

|

|

|

|

Fakespace BOOM3C boom mounted display (Photo: Fakespace,

Inc.)

|

The BOOM (Binocular Omni-Orientation Monitor) from Fakespace

is a head-coupled stereoscopic display device.

Screens and optical system are housed in a box that

is attached to a multi-link arm. The user looks into the box through two holes,

sees the virtual world, and can guide the box to any position within the operational

volume of the device. Head tracking is accomplished via sensors in the links

of the arm that holds the box.

|

|

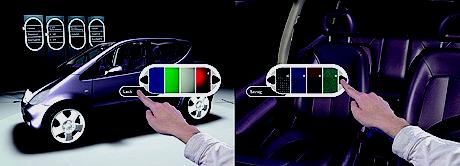

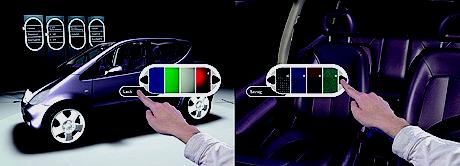

| Art+Com virtual car display. A counter-balanced boom constrains the display

movement as well as supports its weight. (Photo: Art+Com). |

Art+Com VR Control: Note that the display in the previous photo is a touch

screen that enables the operator to interact with the image. (Photo: Art+Com). |

Slide 24 : Large Screen, Reality Center

Large Screen, Reality Center

SGI France

IMMERSIA: salle de projection immersiveEn 1999, l'Irisa a fait l'acquisition

d'un équipement de projection immersive, composé d'une station

Sgi onyx2 tri-pipes et de trois projecteurs barco 1208S.

La projection est faite sur un écran semi-cylindrique d'un rayon de 3,80m,

d'un angle d'ouverture de 135 degrés et d'une hauteur de 2.38m. La projection

peut être en stéréovision à 96Hz ou 120Hz pour obtenir

une vision en relief.

Slide 25 : Workbench

Workbench

Slide 26 : Wedge

Wedge

Slide 27 : CAVE (Cave Automatic Virtual Environment)

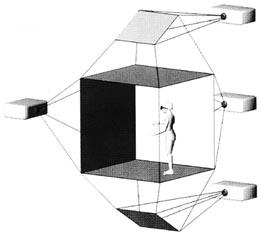

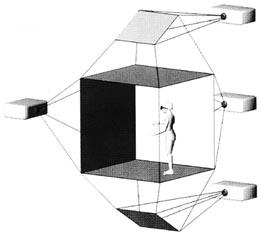

CAVE (Cave Automatic Virtual Environment)

|

|

|

Schematic of an idealized Cave VR system.

Tiled rear projection stereo images appear on up to six faces of the

room in which the operator works. In practice, most Caves have three to

four faces with projections. (Image from: Cruz-Neira, Sandin, DeFanti,

Kenyon and Hart, 1992).

|

The CAVE (Cave Automatic Virtual Environment)

was developed at the University of Illinois at Chicago and provides the illusion

of immersion by projecting stereo images on the walls and floor of a room-sized

cube. Several persons wearing lightweight stereo glasses can enter and walk

freely inside the CAVE. A head tracking system continuously adjust the stereo

projection to the current position of the leading viewer.

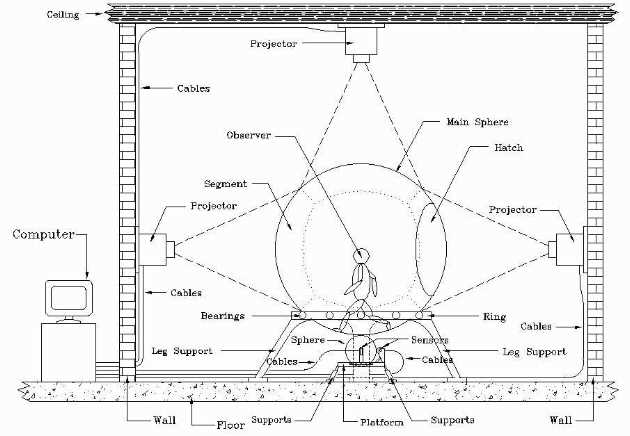

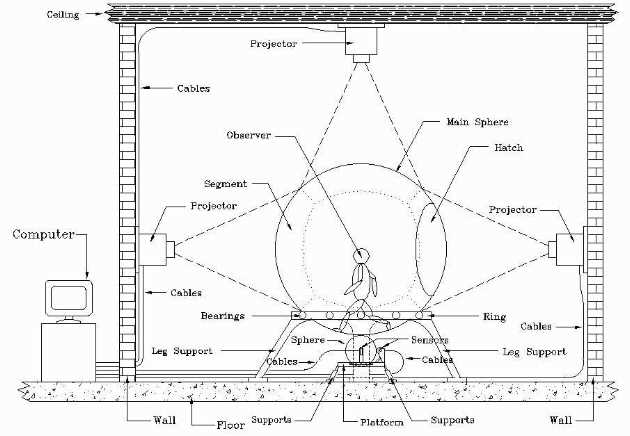

FULLY

IMMERSIVE SPHERICAL PROJECTION SYSTEM

(THE CYBERSPHERE)

Slide 28 : Following issues

Following technical issues

Projector use : projection or transmission ?

issues :

-

how to create stereo vision (3D feeling)

-

size of the device

Screen should transmit polarisation

Refreshment rate should be high

More with color and eyes subject

SGI

SGI